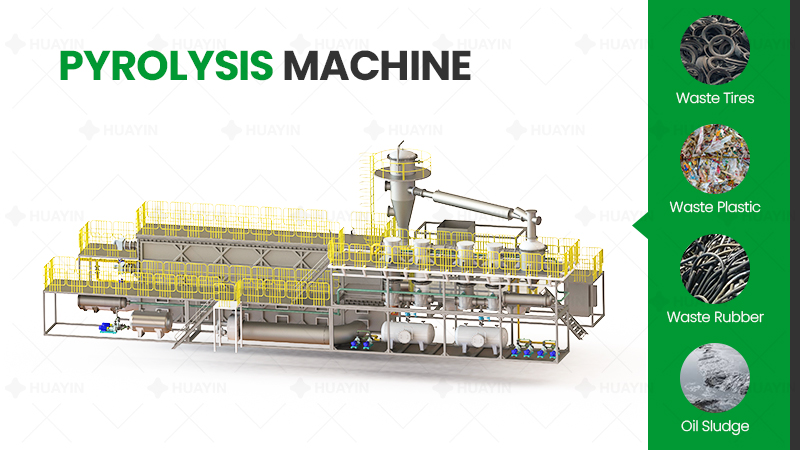

As global awareness of waste management and renewable energy continues to rise, pyrolysis technology has emerged as an innovative solution for converting waste into valuable resources. But what exactly is a pyrolysis machine, and which types of raw materials can it recycle? Let’s explore this in more detail.

What is pyrolysis machine?

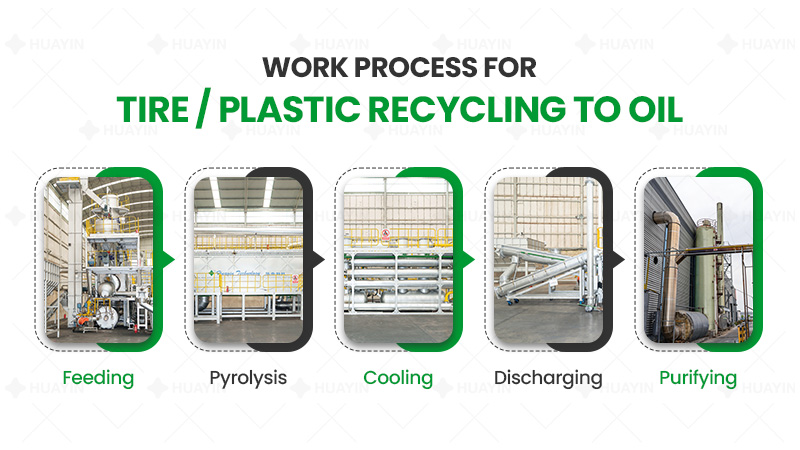

A pyrolysis machine is an advanced recycling equipment that uses high-temperature thermal decomposition in the absence of oxygen to break down complex waste materials into useful products. And the following is a brief display of the working process of pyrolysis machine:

Feeding: feed wastes ( such as waste tires, plastics, oil sludge, rubber) into pyrolysis reactor manually or with auto-feeder machine;

Pyrolysis: heat the pyrolysis reactor to a certain temperature to break down waste into small molecules to come into oil gas. For different waste, the pyrolysis temperature and time also are different, which will not only affect the final pyrolysis effect, but also the quality of the final product;

Cooling: after oil gas generates, going through the cooling system to get liquid fuel oil; in this stage, the cooling effect is also important;

Purifying: during going through the cooling system, the uncondensabe gas goes through the purifying system and be transported to heat the pyrolysis reactor, and the generated final exhaust gas will be further purified to meet the emission standards;

Discharging: in addition to the liquid fuel oil, we can also obtain other valuable by-products, which varies from the recycled waste materials, such as carbon black, steel wire, etc.

In a word, pyrolysis machine is a recycling machine to convert waste into valuable resources with green technology.

What raw material can be recycled by pyrolysis machine?

A pyrolysis machine is versatile and can handle a wide range of feedstocks, mainly organic-based waste. Common raw materials include:

Waste Tires

Old car, truck, or motorcycle tires can be converted into tire pyrolysis oil, carbon black, steel wire, and gas.

Waste Plastics

HD/LD PE, PP, PS, ABS plastics, plastic bags, paper mill waste, plastic cables, aluminum plastics, etc.

Oil Sludge

Oily waste from refineries, drilling operations, or shipyards can be treated to recover valuable oil.

Rubber Products

Besides tires, other rubber scraps like conveyor belts and rubber gloves can also be recycled.

Biomass & Other Organic Waste (optional)

Some specialized pyrolysis machines can handle agricultural residues, wood chips, or municipal solid waste for biochar production.

Why choose pyrolysis machine as waste recycling solutions?

Eco-friendly – Reduces pollution and prevents harmful waste burning or landfilling.

Profitable – Produces valuable byproducts like fuel oil and carbon black.

Flexible – Handles multiple types of waste materials.

Versatile – Process various capacities, designs and configurations for choice, suitable for different investment schemes.

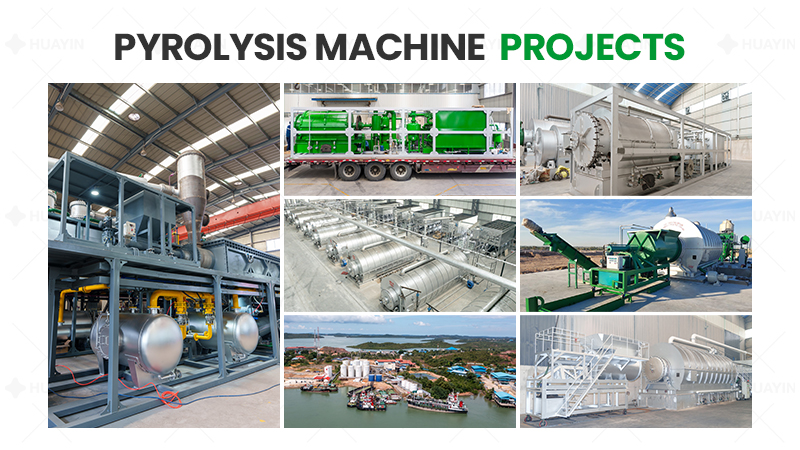

All in all, pyrolysis machine has become a mature technology for waste recycling with lots of years’ development and updating. If you also are interested in pyrolysis machine, welcome to contact us for more detailed information, from machine designs to successful machine projects.