With growing global concerns about pollution and resource depletion, converting waste tires and plastics into fuel oil has become an efficient and eco-friendly recycling solution. This article will make a brief introduction about the process of making fuel oil from tire plastic waste:

1. Feedstock Preparation

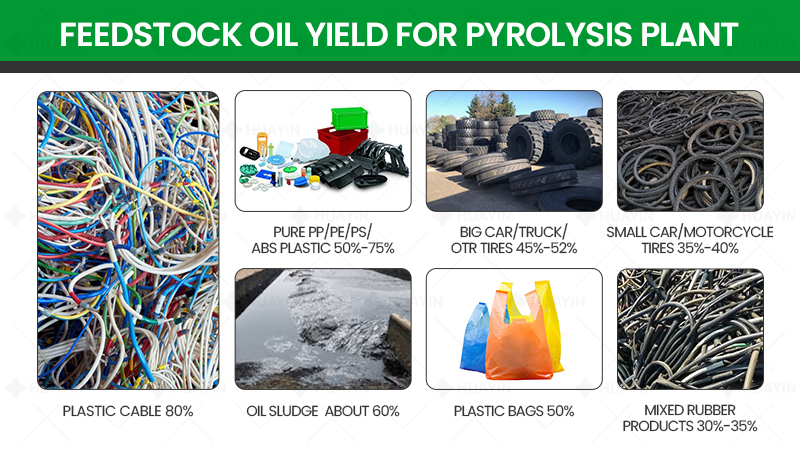

The process begins with collecting and sorting waste tires and plastics. Impurities such as stones, metals, and moisture are removed to ensure smooth operation. Also, if you want to enhance the whole operation efficiency, just make some pretreatment for plastic and tire waste, such as crush them into small pieces or particles. (Note: for plastic waste recycling, PET and PVC are not suitable for making fuel oil with the pyrolysis technology, which will cause corrosion for pyrolysis machine and generate other harmful pollution.)

2. Feeding and Heating

The prepared tire and plastic waste are fed into a sealed pyrolysis reactor. The reactor is gradually heated to a high temperature( different waste needs different pyrolysis temperature) in an oxygen-free environment. This prevents combustion and causes the long polymer chains in tires and plastics to break down into smaller hydrocarbon molecules.

3. Pyrolysis Reaction and Oil Formation

During heating, the tire and plastic waste decompose into oil gas, which passes through a cooling system where it condenses into liquid fuel oil.

4. Exhaust Gas Purifying

Meanwhile, the non-condensable gas is reused to heat the reactor after purifying, significantly saving fuel and improving energy efficiency. And the final flue gas will go through the purifying system to meet the emission standards in various regions.

5. Final Products Discharging

In addition to the fuel oil and non-condensable gas, we can also obtain other products from pyrolysis, such as carbon black and steel wire, which both have wide applications to generate huge profits for customers.

After going through the above process, we can make fuel oil with high quality from tire and plastic waste in the pyrolysis technology. With double environmental and economic benefits, pyrolysis technology has become a popular investment project in the market.

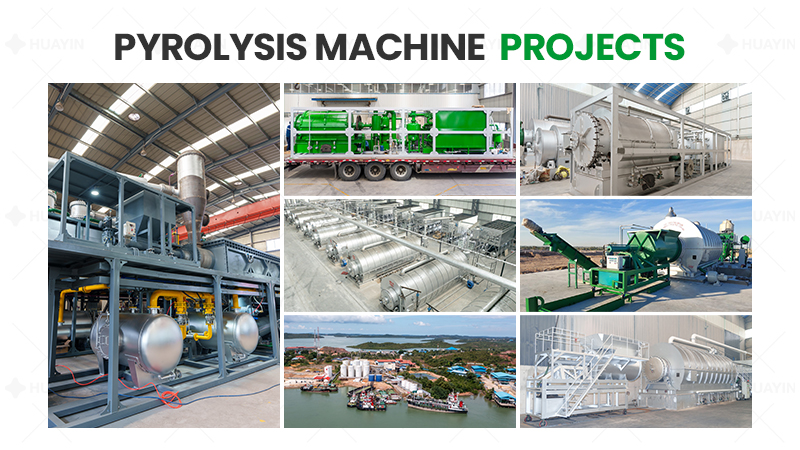

With over 30 years of researching and manufacturing experience, Huayin has provided advanced and reliable waste tire and plastic pyrolysis plants for thousands of customers from over 120 countries. Our equipment features high oil yield, energy-saving design, customization scheme, and comprehensive green emission treatment. From small-scale skid-mounted design to fully automatic continuous systems, Huayin is committed to satisfying clients’ capacity and budget needs.

In a word, making fuel oil from tire plastic waste with the pyrolysis machine is an excellent project with investment value, if you are interested, welcome to contact Huayin directly to get more detailed information.