In a pyrolysis plant, the condensation system plays a key role in converting gaseous byproduct(oil gas) into valuable liquid product(fuel oil). Pyrolysis is a thermal decomposition process that breaks down organic materials, like waste tires or plastics, into three main outputs: fuel oil (liquid), syngas (gas), and carbon black (solid). The condensation system focuses on cooling and capturing the gaseous phase, which is critical for both maximizing product recovery and ensuring energy efficiency.

Temperature Control and Oil Composition: During pyrolysis, gases are produced at high temperatures between 280 and 450°C. The condensation system cools these gases(oil gas) to condense valuable liquid components(fuel oil). If the condensation temperature is not properly controlled, excessively high cooling temperature may result in certain harmful substances in the pyrolysis oil (such as acidic components, tar, etc.) not being effectively separated, thereby affecting the quality of the pyrolysis oil.

Gas Recovery: The condensation system also recycles uncondensed gases (syngas), which, if not properly captured, can contaminate the fuel-oil with undesirable compounds, affecting its chemical stability and aroma. While the recycled syn-gas will be used as heating energy for pyrolysis reactor after purifying to save machine running cost.

Condensation Time and Stability: The duration and speed of condensation influence the stability of fuel-oil. A controlled, slower cooling process helps remove large molecules and unstable compounds, ensuring a more stable and higher-quality oil.

Condensation Method: Different cooling methods (e.g., water-cooled vs. air-cooled) affect the efficiency of the condensation process. Water-cooled systems are generally more effective at rapid cooling, which results in better separation and a cleaner final product. In addition, the water-cooled system generally adopts the circulated water system, which will not cause second water pollution during the whole recycling process.

In summary, a well-designed condensation system is essential for producing high-quality, stable, and pure pyrolysis fuel oil.

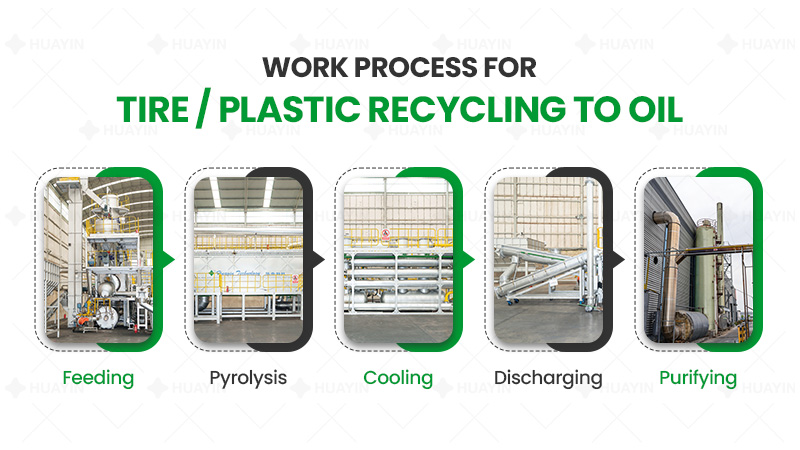

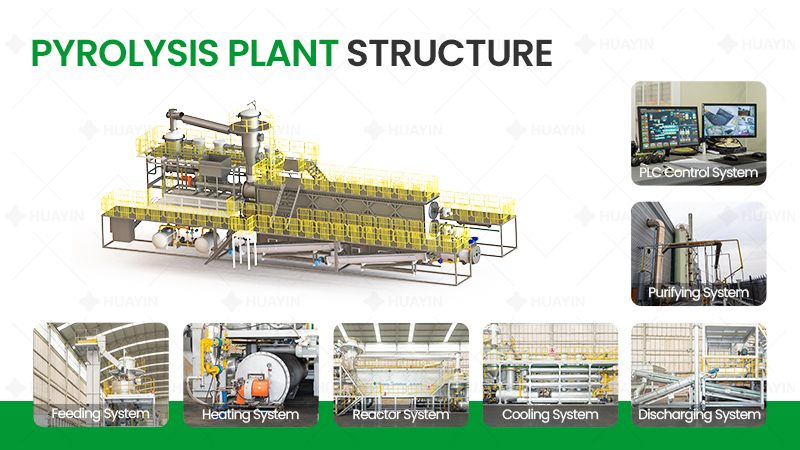

Also, in addition to the condensation system, other configurations in a pyrolysis plant also influence the quality of obtained fuel oil and the whole performance of the pyrolysis plant. Xinxiang Huayin, an experienced pyrolysis plant manufacturer and supplier in China, whose pyrolysis plants have been exported to over 100 countries and received lots of good feedback. And we can also provide customized schemes about the machine designs and configurations based on your situation. For more detailed information, welcome to send your inquiry to us!