With the development of waste management and sustainable resource recovery, pyrolysis machine has become a popular investment to convert waste into valuable resources. Now there are lots of pyrolysis machines in the market, and the pyrolysis machine price is also become an important point for customers to invest in the project. Then what factors will influence the pyrolysis machine price?

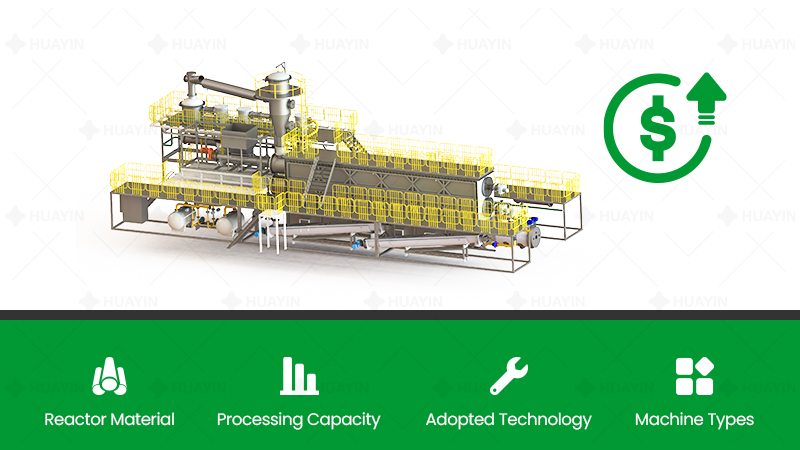

Machine Type

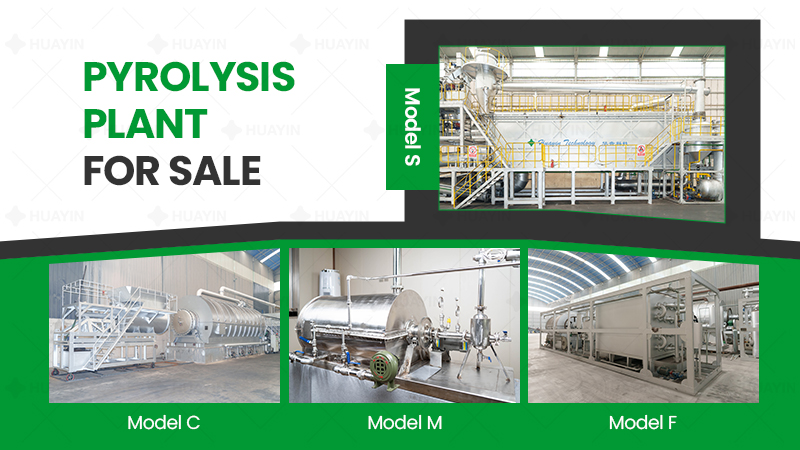

Now there are commonly three types of pyrolysis machines in the market: batch type, semi-continuous design and fully continuous design. Compared with the batch type, the fully continuous design adoptes more advanced technology and can process more waste at one time, so its price is higher than the batch type pyrolysis machine.

Processing Capacity

Pyrolysis machine has various capacities from small scale 10 kg to middle scale 15 tons to large scale 50 tons. Pyrolysis machine with larger capacity needs more time, labor, materials to manufacture, leading to the higher price.

Reactor Material

For pyrolysis machine manufacturing, there are different materials in the market, such as Q245R, Q345R, stainless steel, etc., which has various price. Take the stainless steel as an example, it can withstand high temperature and pressure, and also is corrosion-resistant to enaance the service life of the pyrolysis machine. Of course, its prices is higher.

Machine Configuration

Pyrolysis machine usually consists of feeding system, pyrolysis reactor, heating system, condensation system, slag discharge system, etc. But for these systems, they have different designs and qualities, which adopts different materials and technologies to affect the final price. Also, for some countries which have strict requirements on the environment, they also need to equip the environmental protection system to avoid pollution, which will add extra cost. And if you want to enhance the machine automation and efficiency, you can select the PLC control system, which also needs more price.

Customization And Service

If you require a customized pyrolysis machine to handle specific materials or meet unique operational needs, it will cost more, because the enginner needs to modify the equipment’s overall design, components, materials, and technology. Also, if you need the pyrolysis machine manufacturer to provide additional machine installation and operation guidance service, you need to pay more.

In a word, pyrolysis machine price varies from different factors, if you want to get more detailed information, welcome to consult us directly!