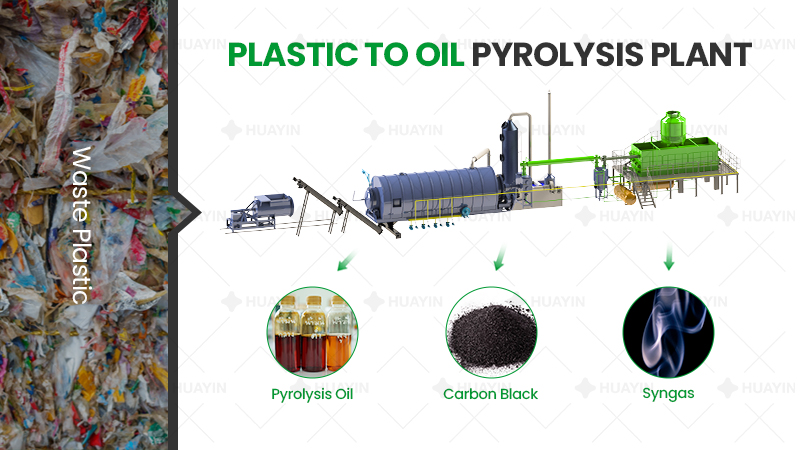

Waste plastic to oil pyrolysis plant can convert waste plastic into fuel oil and carbon black through high temperature, which has economic and environmental benefits. Huayin waste plastic to oil pyrolysis plant not only treats plastic waste, but also obtains renewable resources. The pyrolysis machine is safe, energy-saving and environmentally friendly, and is well received by domestic and foreign customers.

1.Plastic to Oil Pyrolysis Process Principle

Plastic to oil pyrolysis refers to the thermal decomposition of plastic waste at high temperature in the absence of oxygen to produce liquid fuel oil (pyrolysis). The process uses heat to break down larger plastic molecules into smaller oil, gas and carbon molecules. Pyrolysis oil can be used as fuel in ceramic factories, glass factories, power plants, steel plants, boiler plants, etc., to achieve the recycling of waste resources.

2.Plastic to Oil Pyrolysis Process Steps

Plastic to oil pyrolysis refers to the process of thermally decomposing plastic waste to produce fuel oil and other valuable products such as carbon black and combustible gas. The general steps of the plastic to oil pyrolysis process are as follows:

Step1: Waste plastics are fed into a pyrolysis reactor and heated at high temperatures (usually between 300 and 800 degrees Celsius) to decompose into various gaseous, liquid and solid products.

Step2: The gaseous products enter the condensation system, liquefy and become liquid fuel. The oil production process lasts for 12-16 hours. The solid carbon black remains in the pyrolysis reactor waiting to be discharged.

Step 3: After oil production is completed, let the machine cool down for 6 hours before discharging.

Step 4: Discharge the carbon black from the reactor via a U-shaped conveyor.

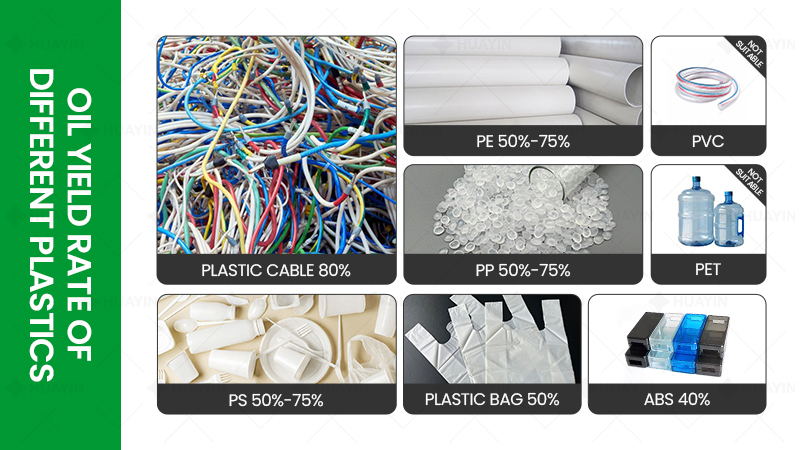

3.Oil Yield of Different Plastic Raw Materials:

Plastic types include HDPE, LDPE, PP, PS, etc., which can produce a high proportion of liquid fuel oil, while PET and PVC are not suitable for pyrolysis. The oil yield of different plastic raw materials is shown in the figure:

4.Plastic to Oil Pyrolysis Plant Purchase Scheme:

Performing the plastic to oil pyrolysis process requires a dedicated production line – waste plastic pyrolysis plant. This waste plastic to oil recovery equipment consists of a feeding system, pyrolysis reactor, burner, oil–gas condensation system, an exhaust gas purification system, etc. The specific configuration of the waste plastic pyrolysis equipment for different customer needs is also different.

As an experienced and reputable pyrolysis equipment manufacturer, huayin company have designed a variety of models of waste plastic pyrolysis machine for you to choose from: laboratory mini model, small free–installation type, batch type and full continuous type. These pyrolysis equipment are carefully designed to withstand high temperatures and maintain an oxygen-free environment to ensure the smooth operation of the plastic to oil pyrolysis process. Its processing capacity ranges from 10kg to 50 tons per day, covering small to large industrial plastic to oil pyrolysis processing scales. Welcome to consult Huayin company for customized waste solutions.