Pyrolysis Technology

Pyrolysis is one of the technologies available to convert biomass to an intermediate liquid product that can be refined to drop-in hydrocarbon biofuels, oxygenated fuel additives and petrochemical replacements. Pyrolysis is the heating of an organic material, such as biomass, in the absence of oxygen. Biomass pyrolysis is usually conducted at or above 500 °C, providing enough heat to deconstruct the strong bio-polymers mentioned above. Because no oxygen is present combustion does not occur, rather the biomass thermally decomposes into combustible gases and bio-char. Most of these combustible gases can be condensed into a combustible liquid, called pyrolysis oil (bio-oil), though there are some permanent gases (CO2, CO, H2, light hydrocarbons), some of which can be combusted to provide the heat for the process. Thus, pyrolysis of biomass produces three products: one liquid, bio-oil, one solid, bio-char and one gaseous, syngas. The proportion of these products depends on several factors including the composition of the feedstock and process parameters.

Application

for used tires recycling

Tire pyrolysis is a well-developed technology for used tires recycling. Pyrolysis process converts used tires to liquid fuel (45%), carbon black (30%), steel wire (15%) and syngas (10%).

Production Ratios

For Waste Plastics Recycling

Plastic types including HDPE, LDPE, PP, PS produce high ratio of liquid fuel oil, while PET and PVC doesn’t contribute to oil yield. The average oil yield from plastic wastes is 50%~75% based on conditions of raw material.

Production Ratios

For oil sludge recycling

It uses customized design of pyrolysis plant to process oil sludge. The oil recovery yield depends on the conditions of raw material, such as the content of impurities and water. Averagely the production ratio could be 60% of fuel oil, 30% of slag and 10% of syngas.

Production Ratios

video introduction

The video introduces how pyrolysis process works, the typical construction of pyrolysis plant and financial forecast.

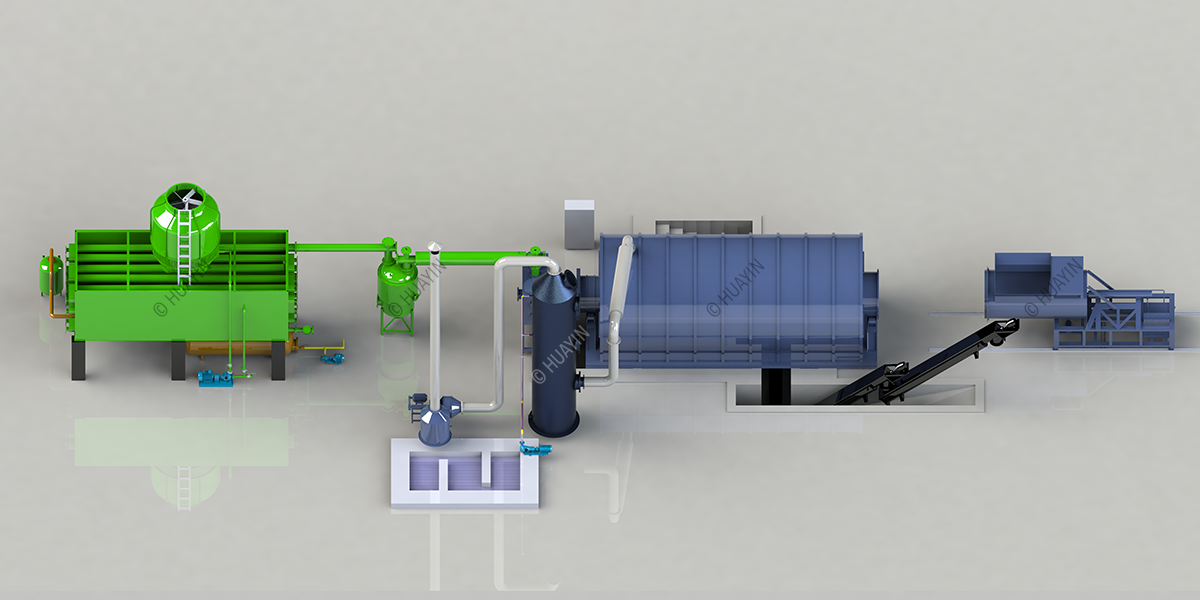

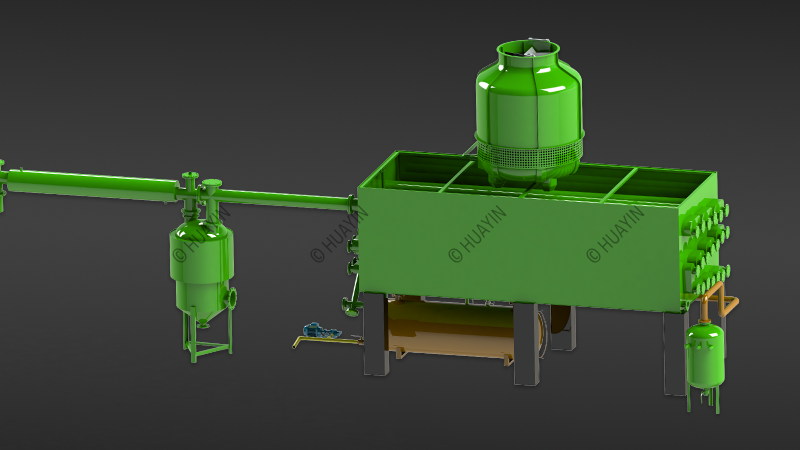

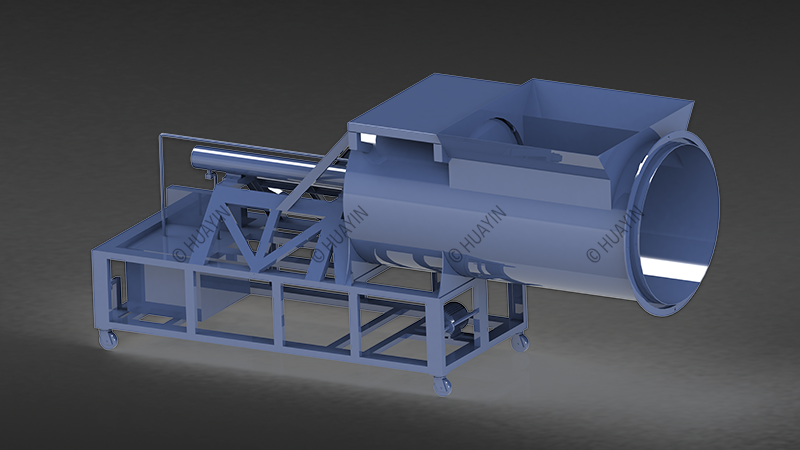

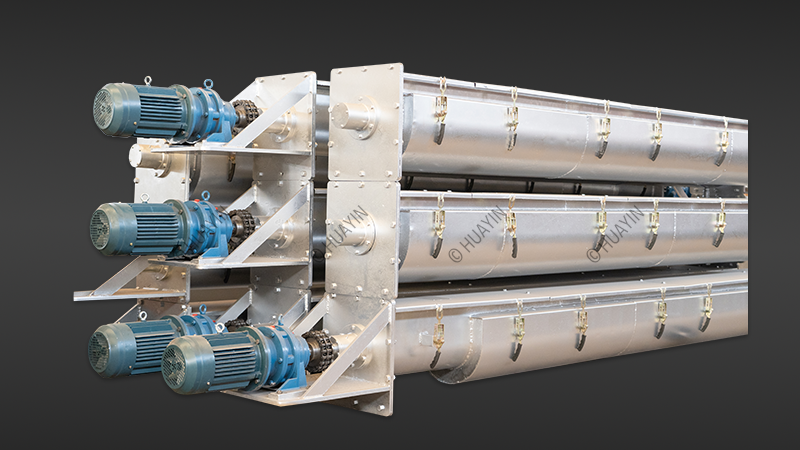

structure of pyrolysis plant

Based on its function, pyrolysis plant is composed of 6 main systems.

Product models

There are 5 model series available for sale.

Model A series

- Unit Capacity: 5/10/15 tons

- Basic choice to start

- Medium emission control

- Onsite installation

Model C series

- Unit Capacity: 5/10/15 tons

- Advanced choice

- High emission control

- Quick installation

Model F series

- Unit Capacity: 750/4000kg

- Installation-FREE

- Low shipping cost

- Modular design

Model M series

- Unit capacity: 10kg

- Mini scale model

- Fully operational

- Installation-FREE

Model S series

- Unit capacity: 30/50 tons

- Continuous type

- High-end choice

- Onsite installation