Many potential investors share common concerns: limited factory space, manageable daily waste tire volumes, or a desire to start with a small-scale trial before committing to larger investments. So, do small, more flexible tyre pyrolysis plant exist in the market?

The answer is: Yes! To meet the diverse needs of different customers, HUAYIN equipment engineers have specially designed and manufactured a series of small tyre pyrolysis plant.

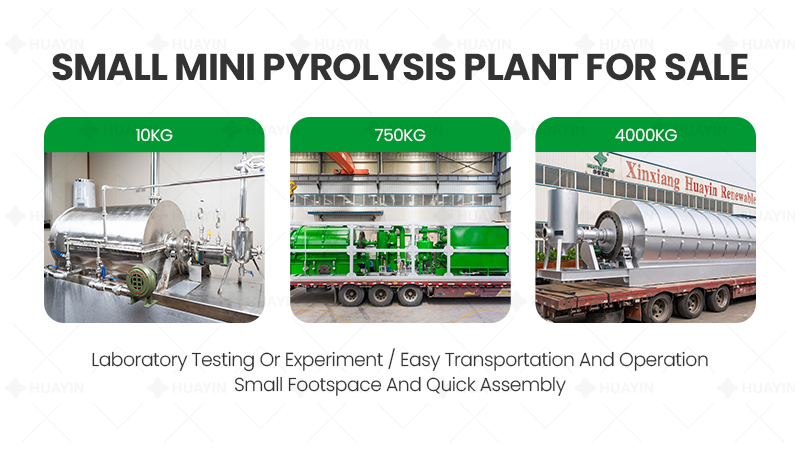

Our Small–Scale tyre Pyrolysis plant Product Line

We offer various models of small tyre pyrolysis plant to ensure there’s always a perfect match for your specific requirements:

➢ 10 kg/batch (Laboratory/Demonstration Model):

Target Users: Universities, research institutions, and environmental protection organizations.

Primary Use: This 10kg pyrolysis plant (Model M) is designed for scientific research and teaching demonstrations. Researchers can use it to test the oil yield of different types of tyres and analyze the composition of oil products. It is also an excellent tool for visually demonstrating the principle of pyrolysis technology to investors.

➢ 750 kg/batch (All-in-One Design):

Target Users: Small tyre recycling plant and enterprises that need to handle scattered waste.

Primary Use: The entire system of this 750kg pyrolysis plant (including the pyrolysis reactor, cooling system, and slag discharge system...) is integrated in a standardized frame structure base, which is very convenient for transportation and installation. It is particularly suitable for scenarios with limited space or requiring mobile operations, and is an ideal starting point for small-scale business operations.

➢ 4000 kg/batch (Small Commercial Production Model):

Target Users: Start-up companies, small to medium-sized factories, and individual investors seeking business expansion.

Primary Use: This 4000kg pyrolysis plant possesses full commercial production capabilities, yet its footprint and investment cost are significantly lower than larger pyrolysis plant (10+ tons). It allows you to launch a sustainable, cash-flow-generating commercial project with a relatively controlled budget, making it the best choice for market validation and accumulating operational experience.

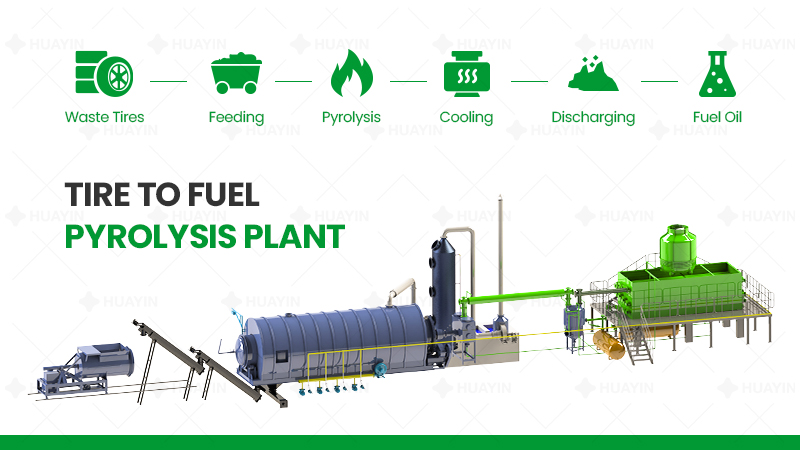

How Does Small tyre Pyrolysis plant Work?

Although tyre pyrolysis plant have become smaller in size, they follow exactly the same working principle as large tyre pyrolysis plant. The entire working process can be simplified into four core steps:

- Feeding: Manually or through an automatic feeding plant, waste tyres are loaded into the pyrolysis reactor, and then the furnace door is sealed.

- Heating and pyrolysis: Start the heating system (usually using electricity or fuel oil/gas) to heat the reaction vessel. When the temperature reaches approximately 250°C, the tyre begins to decompose, generating oil vapor. As the temperature continues to rise to 400-450°C, a large amount of oil and gas will be produced.

- Cooling & Collection: The high-temperature oil and gas generated will enter the condensation system. Here, the oil and gas are rapidly cooled, liquefied into fuel oil and flow into the storage tanks. A small amount of unliquefied combustible gas will be collected and used to assist in heating the reaction vessel, thus saving energy.

- Discharging & Maintenance: After the entire batch of reactions is completed and fully cooled, open the furnace door and remove the remaining solid residue (carbon black) after the reaction.

Advantages of Small tyre Pyrolysis plant

- Low investment cost: The initial purchase cost is much lower than that of large-scale equipment.

- Flexible site: Small foot space and low requirements for infrastructure.

- Easy operation: The process is simplified, making it easier to operate and maintain.

- Controllable risks: It is highly suitable as a “touchstone” for market testing or project validation.

Are you ready to embark on your journey of tyre waste recycling? Contact us and HUAYIN engineers will assist you in choosing the most suitable small tyre pyrolysis plant for your needs.