Is oil-based mud a hazardous material? Yes, it is. Oil-Based Mud (OBM) is a type of drilling fluid used primarily in oil and gas drilling operations, which is classified as a hazardous material in most areas and requires special handling. Generally, the most suitable recycling solution is pyrolysis technology, which can not only recover it into valuable products, but also can reduce pollution.

Why oil-based mud can’t be recovered with common solution?

Oil-based mud cannot be recycled using common methods due to its complex composition, including stable water-in-oil emulsions, toxic chemicals, heavy metals, and non-biodegradable hydrocarbons. Traditional physical, chemical, or biological treatments are ineffective at separating and recovering these components safely. Additionally, strict environmental regulations prohibit direct disposal or burning. As a result, advanced technologies like pyrolysis are required to break down the waste, recover valuable oil, and ensure environmentally safe treatment of the remaining solids.

How pyrolysis machine recover the oil-based mud?

First, oil-based mud is fed into the pyrolysis furnace via a sealed screw conveyor; during pyrolysis at a certain high temperature without oxygen, light oil components are distilled, and heavy oils break down into volatile hydrocarbons, resulting in recoverable oil and gas, water vapor, non-condensable gases, and solid residues. The oil and gas mixture then passes through the condensation system where condensable components become liquid oil for storage, while flammable gases are directed to the combustion system to supply heat. Finally, solid residues are cooled and discharged, and flue gases are purified before being safely emitted.

What valuable products can we recover from oil-based mud with pyrolysis machine?

Pyrolysis Oil (≈60%)

The process recovers approximately 60% pyrolysis oil, which can be directly used as heating fuel in heavy industrial equipment such as cement kilns, steel mills, metallurgical plants, glass factories, and power stations. Additionally, it can be further refined into lower-grade diesel to expand its range of applications.

Solid Slag (≈30%)

Around 30% of the output is solid slag, primarily composed of inert materials. This residue can be repurposed as a construction material, ideal for use in roadbed foundations, bricks, or other building products.

Syngas (≈10%)

Approximately 10% of the yield is synthetic gas (syngas), which, after purification, can be reused as a clean and efficient fuel to heat the pyrolysis reactor itself, enhancing the system’s energy efficiency and reducing operational costs.

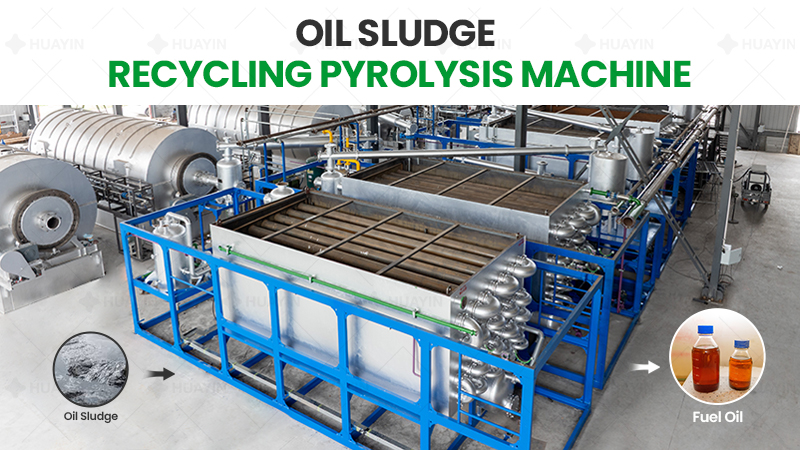

And in addition to the oil-based mud, pyrolysis machine can also recover other kinds of oily sludge, such as oilfield sludge, refinery sludge, tank bottom sludge, separator sludge, slop oil, marine sludge, oily waste, industrial oily sludge, waste lubricant sludge, etc. For more information, just feel free to contact us directly!