Plastic pyrolysis technology converts waste plastics into fuel oil, but the quality of pyrolysis oil is often uneven. Huayin will introduce a comprehensive optimization plan from raw material selection to subsequent processing to help you produce higher quality plastic pyrolysis oil products.

Raw material selection and pretreatment

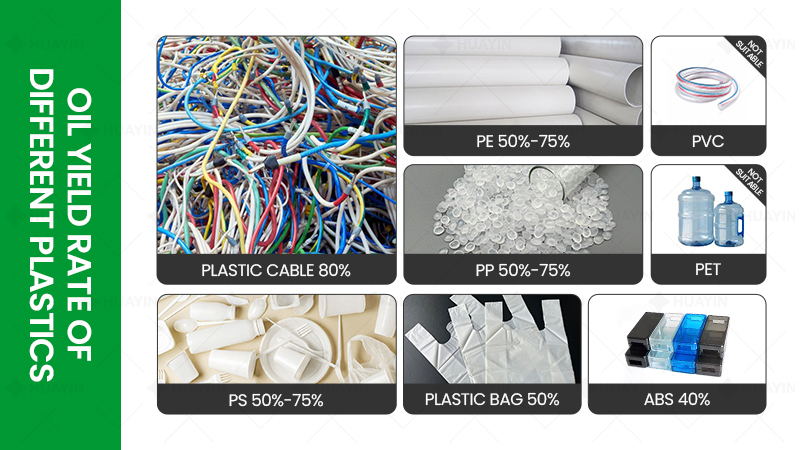

The oil yield of waste plastics is related to the type and purity. Pure waste plastics have a higher oil yield. For example, the oil yield of pure PE plastics can reach 95%, while the oil yield of pure PP plastics can reach 90%. Therefore, choosing pure waste plastics as raw materials can improve the quality of pyrolysis oil. In addition, the raw materials can be properly sorted, cleaned and dried to make the quality of the finished pyrolysis oil better.

Pyrolysis process optimization

In the working process of plastic pyrolysis machine, precise temperature control and efficient condensation system are the key to improving the quality of plastic pyrolysis oil.

Waste plastic materials are complex and there is no precise optimal oil output temperature. During the plastic pyrolysis machine process, temperature control is critical, and the pyrolysis temperature directly affects the proportion of different products and the quality of pyrolysis oil. Studies have shown that the optimal pyrolysis temperature range is usually between 400-500 ℃.

Efficient condensation technology can quickly cool pyrolysis vapor, which can not only reduce the loss of light components, but also make the pyrolysis oil have fewer impurities and more concentrated distillation range, thereby improving the quality of pyrolysis oil.

Refining treatment

After the plastic pyrolysis oil is produced from the reactor, it usually contains a variety of impurities and undesirable components, and must be systematically treated to meet the standards of fuel or chemical raw materials. The non-standard diesel obtained by refining these pyrolysis oil can be widely used in boilers, generators, burners, agricultural machinery, construction machinery and ship engines.

Through the triple guarantee of raw material control, process optimization and refining treatment, the quality of plastic pyrolysis oil can be significantly improved, opening up a broader market prospect for the resource utilization of waste plastics.

If you want to engage in the pyrolysis of waste plastics to make oil business, Huayin Company is your best choice. We are committed to providing you with advanced waste plastic pyrolysis plant, pyrolysis oil distillation equipment and comprehensive customized solutions. Contact us now to get more relevant information!