Waste tire pyrolysis machine is an effective method for converting used tires into valuable products such as tire pyrolysis oil, carbon black, steel wire, and combustible gas. For businesses investors involved in pyrolysis industry, maximizing output is crucial to achieving higher profitability and operational efficiency. Here are key strategies to increase output in waste tire pyrolysis processing:

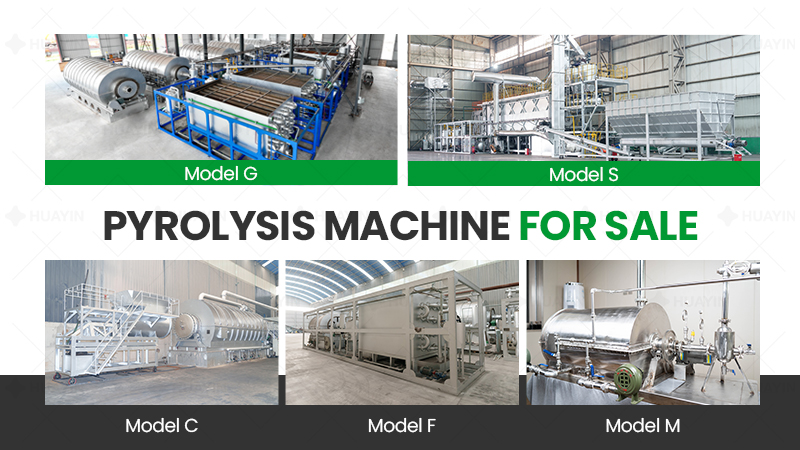

1. Choose the Right Type of Waste Tire Pyrolysis Machine

The type of pyrolysis machine plays a significant role in determining productivity. Compared with traditional batch and semi-continuous systems, fully continuous pyrolysis machines offer higher automation, shorter downtime, and increased processing capacity. Upgrading to a continuous system can significantly boost daily output while reducing labor costs.

2. Proper Raw Material Preparation

Proper shredding and drying of waste tires prior to their introduction into the reactor are critical for enhancing heat transfer efficiency and promoting more thorough pyrolysis. Reducing tire fragments to smaller size expands the total surface area, a key factor that accelerates the reaction rate and boosts oil yield significantly.

3. Improve Pyrolysis Temperature and Heating Control

Efficient heating systems and precise temperature control are essential for high output. Installing PLC automatic control systems allows for accurate regulation of the reactor’s temperature, ensuring optimal pyrolysis conditions and minimizing energy waste.

4. Use High-Quality Condensation Systems

Upgrading your condensation system ensures better recovery of pyrolysis oil from oil gas. High-efficiency condensers improve oil yield and reduce the amount of uncondensed gas, enhancing overall product output.

5. Train Skilled Machine Operators

Invest in operator training to ensure your team understands how to run the system efficiently. Skilled technicians can identify issues early, adjust parameters as needed, and keep the pyrolysis plant running at stable performance.

6. Strengthen Equipment Maintenance

Regular maintenance of pyrolysis equipment is essential for stable operation and high efficiency. During processing, timely cleaning ensures effective heat transfer and maintains optimal reaction temperatures. It’s also important to inspect auxiliary systems such as feeding, discharging, and cooling systems. Proper maintenance helps prevent downtime and ensures continuous, efficient output.

7. Increase the Utilization of By-Products

Maximizing the use of pyrolysis by-products helps boost the overall output value. Carbon black can be further processed for use in the rubber or ink industries, while recovered steel wire can be recycled in the steel industry. Exploring more applications for these by-products increases the economic return of the process, motivating higher production levels.

In summary, increasing output in waste tire pyrolysis processing requires several tips to pay attention to. Huayin company, prefessional waste tire pyrolysis machine manufacturer and supplier, has cooperated with lots of customers in over 100 countries and helped them successfully set up the pyrolysis machine projects. Excellent machine quality and overall engineer service, also can provide customized machine scheme to meet the various demands, if you are interested in the waste tire pyrolysis processing project, just feel free to send the inquiry to us!