You have already perceived the huge business opportunities hidden behind the energy transformation of waste plastics and are ready to put this vision into practice. However, choosing the right plastic pyrolysis equipment is the key to the success or failure of the entire project. There are a wide variety of choices in the market with huge price differences. How can one make a wise and time-tested decision?

As experts with over a decade of experience in the industry, we have summarized an ultimate purchasing guide for you. Rather than teaching you how to “buy”, it’s more about sharing with you how to “invest” to ensure that every dollar you spend is allocated to true value.

Step 1: Look Beyond Price, Focus on Core Technology

Price is important, but it should never be the sole criterion. A cheap but inefficient machine will continuously erode your profits during its operational life. When evaluating equipment, you must investigate these core technical points:

Is the pyrolysis reactor designed as a horizontal rotary type? Is the material of the pyrolysis reactor made of boiler-specific steel plates such as Q245R or Q345R? Horizontal reaction vessels can ensure that raw materials are heated uniformly at 360°, making the pyrolysis of raw materials more thorough and naturally resulting in a higher oil yield. The material of the reaction vessel directly affects the safety and service life of the equipment.

Plastic pyrolysis oil yield: This is the core indicator of your investment return. Don’t readily believe verbal promises. Please ask the pyrolysis plant manufacturer to provide the average oil yield data based on specific plastic types (such as PP, PE, PS), and inquire about the technologies they use (such as catalysts, reactor structures) to achieve a high oil yield.

Energy-saving design: Operating costs are the key to long-term profits. Does the equipment have a combustible gas recovery system? Recovering the combustible gas generated during production as the heating fuel for the reaction vessel can significantly reduce your daily operating expenses.

Step 2: Safety is An Unbreachable Bottom Line

Pyrolysis projects involve high temperature and high pressure, and safety is the top priority in production. A responsible plastic pyrolysis machine must be equipped with:

Multiple safety devices: Check whether it is equipped with an automatic alarm system (over-temperature, over-pressure), emergency relief valve, anti-backfire device (water seal), etc.

Welding process: It is required to check the welding details of the equipment. Professional plastic pyrolysis machine have smooth and firm weld seams that can pass X-ray flaw detection, eliminating potential safety hazards.

Degree of operation automation: The highly automated feeding and slag discharge system not only enhances efficiency but also prevents workers from operating in high-temperature and harsh environments, fundamentally improving production safety.

Step 3: Scrutinize Environmental Compliance

Environmental protection regulations are becoming increasingly strict. A set of plastic pyrolysis plant that fails to meet local environmental protection standards may turn into a pile of scrap iron at any time.

- Waste gas treatment: Inquire about their waste gas purification plan. Is it simple water washing or multi-stage composite treatment? It is required that the pyrolysis equipment manufacturer provide the environmental impact assessment reports or emission data of past projects as references.

- Wastewater recycling: Is the cooling system designed for circulating water? This not only saves water resources but also avoids the discharge of production wastewater.

- Solid waste treatment: For the product carbon black, can the manufacturer provide subsequent utilization suggestions or corresponding deep processing equipment (such as grinding, granulation)?

Step 4: Choosing a Reliable Manufacturer

The last and most important step is to choose a reliable pyrolysis machine manufacturer. What you purchase is not merely a plastic pyrolysis machine, but a complete set of services and long-term technical support.

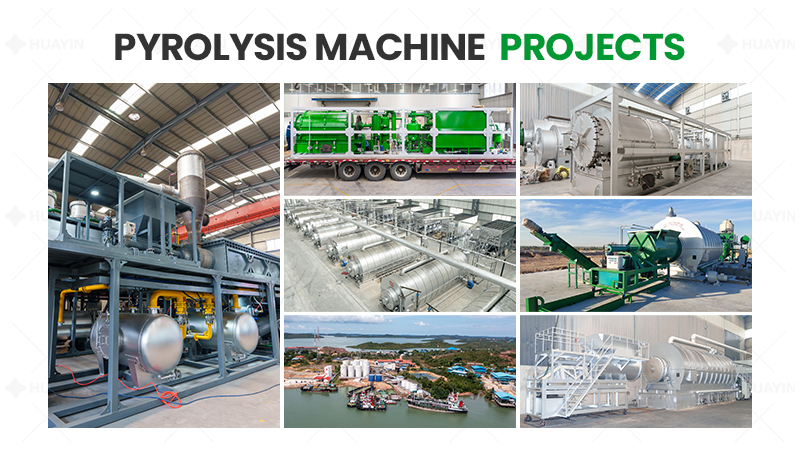

- On-site inspection is essential: photos and videos can be beautified, but the real production workshop, processing equipment and team appearance cannot be faked. Please be sure to visit the factory in person. Seeing is believing.

- Project Experience and Cases: A mature manufacturer must have numerous successful cases worldwide. Please ask them to provide project cases in your area or under similar climatic conditions.

- Technical team and after-sales service: Who will install and debug your equipment? Can the company provide training for operators? A manufacturer with a strong team of engineers and a complete after-sales system is a solid backing for the long-term stable operation of your project.

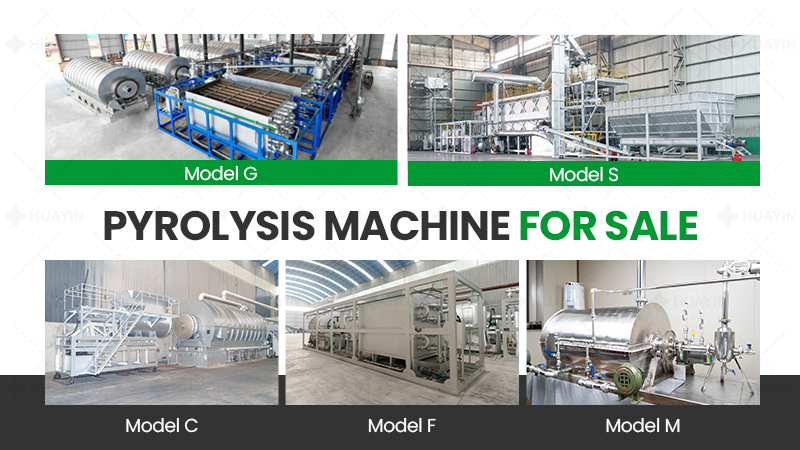

Purchasing a waste plastic pyrolysis machine is a major investment decision. Huayin Company encourages you to be a “picky” buyer and examine every detail with a professional eye. We are fully confident in the technology, safety and quality of our products, and we always welcome you to bring this “Purchasing Guide” to our factory for inspection.

What we look forward to is not a one-off transaction, but establishing a long-term and win-win partnership with you. Contact us immediately to start your on-site inspection journey!