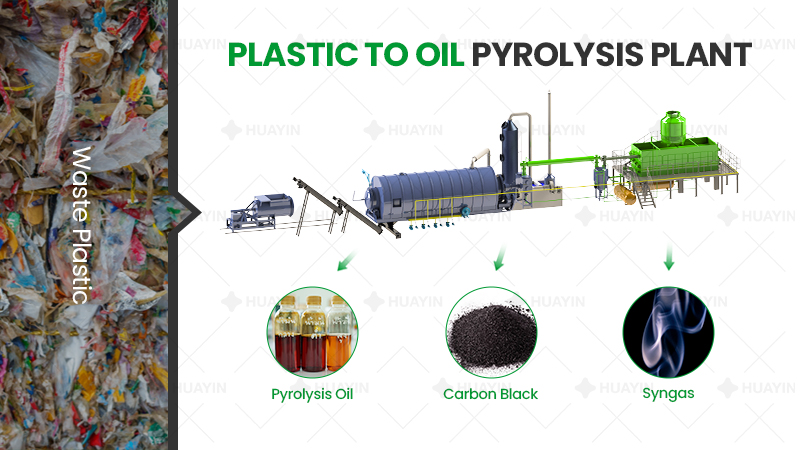

In the era’s wave of circular economy and sustainable development, waste plastics are transforming from a thorny environmental issue into a highly potential energy treasure trove. This article will systematically analyze for you why plastic is being converted into fuel and how we can turn this vision into an efficient and reliable industrial reality through leading technologies and equipment.

1. Driving Force: Why Do We Convert Plastic into Fuel?

Converting plastic into fuel is not only a business opportunity but also a responsibility and wisdom bestowed by The Times. Its core driving force stems from three major aspects:

- Environmental drive: Traditional landfill and incineration methods have caused secondary pollution to the land, water sources and atmosphere. Plastic oil refining technology offers a closed-loop solution that can “digest” plastic waste from the source and transform it into high-value products, which is a fundamental way out for addressing “white pollution”.

- Energy-driven: Petroleum is a non-renewable resource, and the chemical nature of plastics is the same as that of petroleum, being solid “hydrocarbons”. On average, 500 to 800 kilograms of fuel oil can be extracted from each ton of waste plastic, making it a stable and reliable alternative energy source, which helps alleviate energy shortages and ensure energy security.

- Economic drive: On the one hand, the demand for waste plastic treatment in countries around the world is becoming increasingly urgent, providing a vast raw material market; On the other hand, the fuel oil, carbon black and combustible gas produced all have clear industrial uses and market value. This endows the waste plastic oil refining project with extremely high potential for investment return, making it a typical circular economy model that turns waste into treasure.

2. Core technology: Pyrolysis

Core technology for converting plastic to fuel is Anaerobic Pyrolysis.

The principle is to heat the plastic to a high temperature of 400-500°C in a completely sealed container (pyrolysis reactor). In an oxygen-free or extremely low-oxygen environment, the long-chain polymer structure of plastics will break and reorganize, decomposing into small-molecule oil and gas. This process avoids combustion and thus does not produce harmful substances such as dioxins. It is a clean and efficient chemical reconstruction process.

3. Key equipment: A complete industrial system

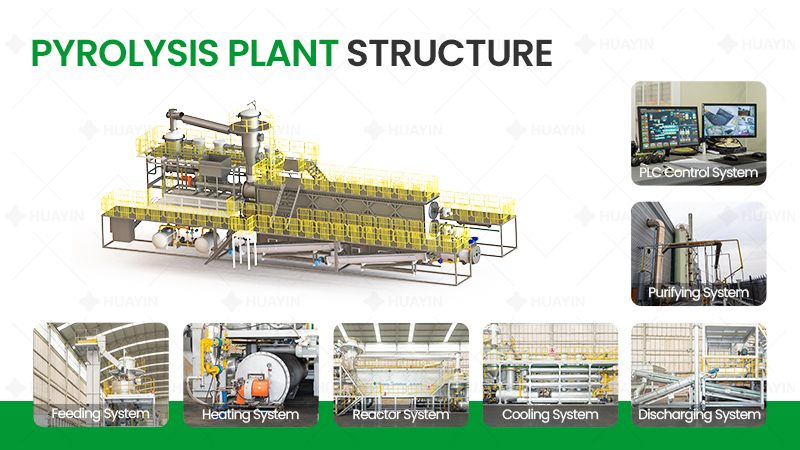

A set of professional waste plastic pyrolysis plant is not a single machine, but a complete industrial system composed of multiple systems. Our production line mainly includes:

- Automatic feeding system: Enhance efficiency and ensure safety.

- Pyrolysis reactor system: Responsible for completing the core pyrolysis reaction.

- Oil and gas condensation system: Efficiently liquefied oil and gas, converting it into liquid fuel.

- Purification system: Treats the smoke and dust generated during the heating process to ensure environmental protection compliance.

- Carbon black slag discharge system: Automatically discharges the solid product (carbon black) after the reaction.

- PLC system: Intelligently controls the entire production process and monitors various operating parameters.

4. Working Process of Transformation from Plastic to Fuel

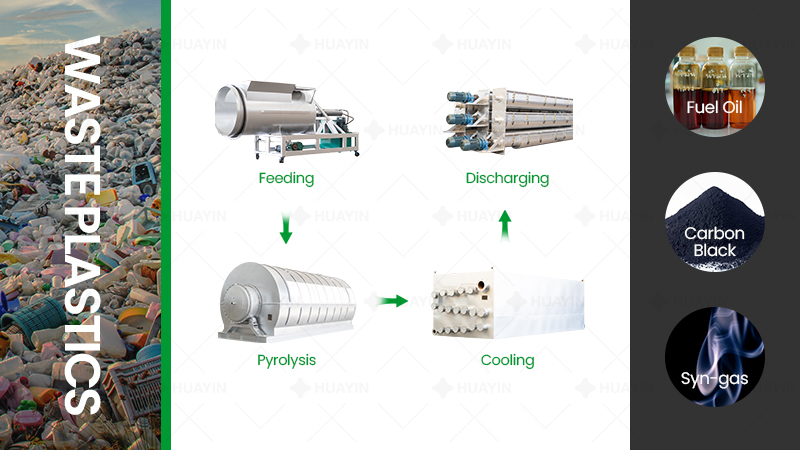

Huayin waste plastic pyrolysis plant simplifies complex chemical processes into four stable and controllable industrial steps:

- Feeding: The pre-treated plastic fragments are sent into the sealed pyrolysis reactor through an automatic feeder.

- Pyrolysis: The reaction vessel is stably heated. When the temperature reaches the set value, the plastic begins to crack in large quantities, generating high-temperature oil vapor.

- Cooling: High-temperature oil and gas enter the efficient condensation system, are rapidly cooled, liquefied into fuel oil, and then collected in the oil storage tank. The uncondensed combustible gas is purified and recycled as fuel.

- Slag Discharge and Purification: After the reaction is completed, the system automatically discharges the carbon black.

Meanwhile, the smoke and dust generated throughout the production process are treated by a multi-stage purification system to achieve standard emissions.

We are well aware that every investment you make carries great expectations. Huayin sincerely invite you to visit our production base for an on-site inspection and experience our outstanding technical strength and exquisite craftsmanship in person. Let’s join hands to transform the challenge of plastic pollution into boundless business opportunities for green energy.