distillation Technology

Distillation is the process involving the conversion of a liquid into vapor that is subsequently condensed back to liquid form. In the application for recycling of waste engine oil and processing of pyrolysis oil, the feedstocks are heated to become gas state then the gas gets liquified by condensing and becomes liquid fuel. In the distillation process, the impurities are removed from the feedstocks.

Application

For Waste Engine oil recycling

Waste engine oil is converted to heavy diesel through distillation process. The approximate oil yield is around 85%.

Production Ratios

For Distillation Of Pyrolysis Oil

By distillation process, the quality of pyrolysis oil is improved. The average oil yield is 90%.

Production Ratios

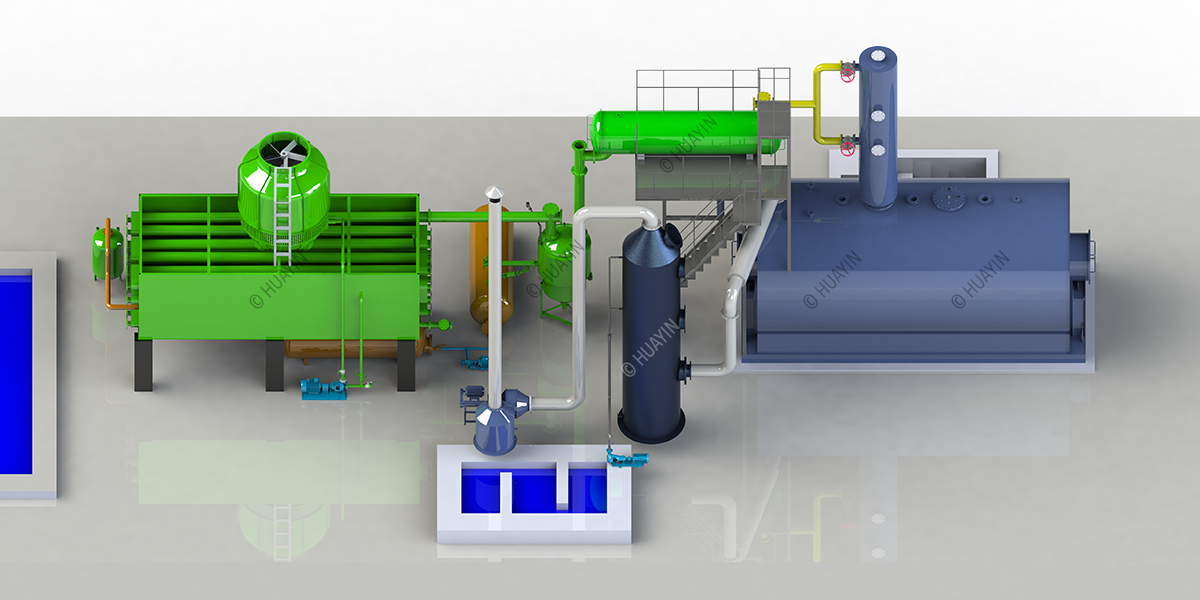

Structure of distillation Plant

Based on its function, distillation plant is composed of 6 main systems.

Product models

There are 5 model series available for sale.

Model A series

- Unit Capacity: 2/5/10 tons

- Basic choice to start

- Medium emission control

- Onsite installation

Model C series

- Unit Capacity: 2/5/10 tons

- Advanced choice

- High emission control

- Quick installation

Model F series

- Unit Capacity: 750/4000kg

- Installation-FREE

- Low shipping cost

- Modular design

Model M series

- Unit capacity: 10kg

- Mini scale model

- Fully operational

- Installation-FREE