Pyrolysis technology is not suitable for all plastics. Pyrolysis is a process that heats plastic materials to high temperatures to break their molecular chains and convert them into smaller molecules, such as hydrocarbons and other chemicals. This technology has the potential to treat some difficult-to-recycle plastic waste, especially those that are difficult to process through traditional mechanical recycling methods.

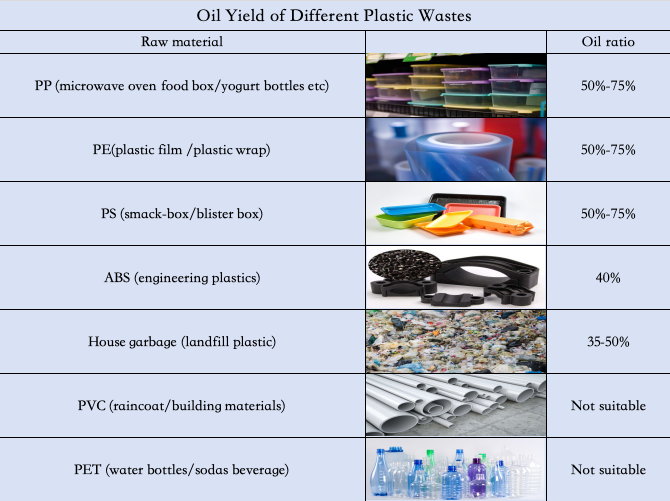

However, not all types of plastics are suitable for pyrolysis. For example, polyvinyl chloride (PVC) and polyethylene terephthalate (PET) are difficult to process through pyrolysis technology. This is because PVC may release toxic hydrogen chloride gas during pyrolysis, while PET requires higher temperatures and specific catalysts to achieve effective pyrolysis.

For other plastics, such as polyethylene(PE), polypropylene(PP), and polystyrene(PS), pyrolysis technology can convert them into useful fuels or chemical materials. This method is significant for treating plastic waste, achieving resource recovery, and reducing environmental pollution.

Pyrolysis technology can be used as an effective treatment solution for waste plastics and has irreplaceable advantages in creating alternative energy and reducing pollution.