Many companies and investors are asking: Can plastic pyrolysis oil be sold directly or used as fuel? The answer is sure, but certain conditions must be met.

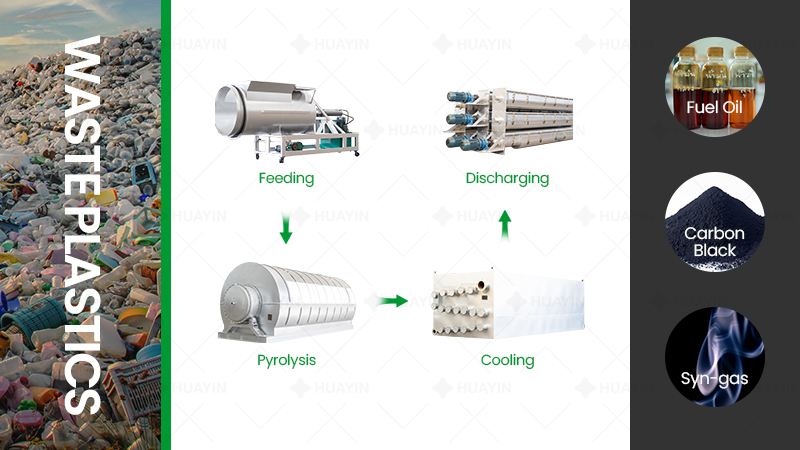

Plastic pyrolysis oil is a final product generated by the pyrolysis process of waste plastics. It is rich in hydrocarbons and has a calorific value comparable to diesel. In industrial heating scenarios, plastic pyrolysis oil can replace traditional fuels and be used in boilers, furnaces and other equipment; in terms of power supply, it can provide power for diesel generators. At the same time, properly treated plastic pyrolysis oil can also be sold directly to energy companies and industrial manufacturing plants to achieve resource recycling.

However, the use and sale of plastic pyrolysis oil is not without barriers. From a quality perspective, a series of fine processes such as filtration, desulfurization and dechlorination are required to strictly control the impurities in plastic pyrolysis oil. Only by ensuring that the quality of the oil meets the standards can the needs of different application scenarios be met. From a compliance perspective, plastic pyrolysis oil must meet local environmental protection regulations and fuel quality certification requirements, which is the basic condition for entering the market.

In actual applications, there have been many successful cases. For example, a Malaysian company used plastic pyrolysis oil to supply a cement plant and achieved a payback in just 8 months. Our company’s plastic pyrolysis machine can ensure the stable production of plastic pyrolysis oil with precise temperature control and advanced purification technology, helping enterprises to seize this business opportunity. Whether you are interested in the plastic pyrolysis oil processing process or want to know the specific details of Huayin pyrolysis machine, please feel free to contact us for more information.