Cement production is an energy-intensive process that traditionally relies on fossil fuels such as coal, petroleum coke, and natural gas. However, these fuels not only drive up operational costs but also generate large amounts of CO₂ emissions. As global industries move toward sustainability, pyrolysis oil—produced through waste recycling using a pyrolysis plant—has emerged as a promising and environmentally responsible fuel alternative for cement plants.

What is Pyrolysis Oil?

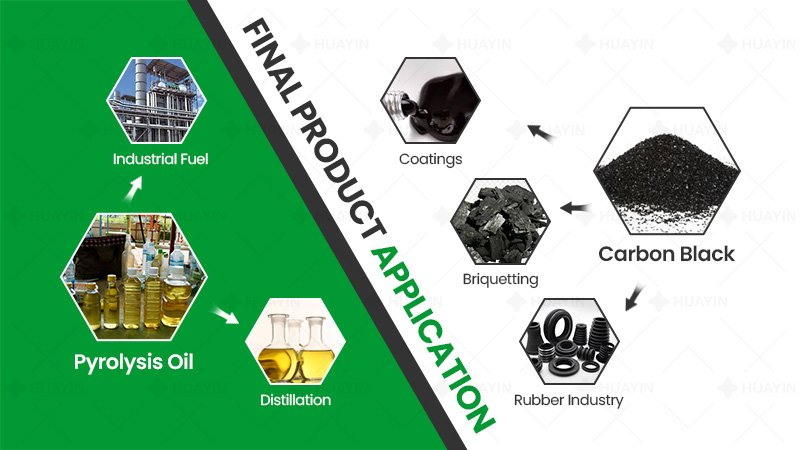

Pyrolysis oil is a liquid fuel obtained by heating organic waste materials, including plastics, rubber, oil sludge, and tires, in the absence of oxygen. During this thermal decomposition process, long-chain hydrocarbons are broken down into shorter molecules, resulting in three primary products: liquid oil, non-condensable gas (syngas), and solid carbon black.

The resulting liquid, known as pyrolysis oil (or fuel oil), has a dark brown to black appearance and offers a high calorific value of 38–45 MJ/kg—comparable to conventional fossil fuels like diesel or heavy oil. This makes it a reliable and powerful alternative fuel for various high-energy industries.

Advantages of Pyrolysis Oil as an Alternative Fuel for Cement Plants

1. Environmental Benefits

Using pyrolysis oil in cement kilns greatly reduces carbon emissions and dependence on traditional fossil fuels. By converting waste tires, plastics, and oil sludge into usable energy, the pyrolysis process helps minimize landfill accumulation and supports a circular economy.

Modern pyrolysis plants are equipped with advanced emission control and environmental protection systems, ensuring the entire process is pollution-free and compliant with global environmental standards.

2. Economic Benefits

Pyrolysis oil offers a cost-effective and efficient replacement for conventional fuels like coal or heavy oil. Its high energy density ensures excellent combustion performance in cement kilns, while the pyrolysis process can convert approximately 45%–60% of waste materials into valuable fuel oil.

This not only provides cement plants with a stable and affordable fuel source but also reduces exposure to the fluctuating prices of fossil fuels, ultimately improving operational efficiency and profitability.

Beyond cement production, pyrolysis oil can also be widely applied in other industrial sectors such as boilers, steel plants, glass manufacturing, and heavy machinery operations, highlighting its versatility as a renewable energy source.

As a leading manufacturer and supplier of waste pyrolysis plants, Huayin Company is committed to continuous innovation and technological advancement. Our equipment ensures high oil yield, stable operation, and strict environmental compliance—helping clients produce premium-quality pyrolysis oil for industrial fuel applications.

If you are looking for a sustainable, reliable, and economical fuel alternative for your cement plant or other facilities, Huayin pyrolysis plant is your ideal choice. Contact us today to learn more about how we can support your clean energy transition!