Pyrolysis equipment is widely used to convert waste materials—such as waste tires, plastics, rubber and oil sludge—into valuable fuel oil.

1. Basic Working Principle of Pyrolysis Equipment

Pyrolysis equipment works by heating organic waste materials inside a sealed reactor without oxygen. When the temperature reaches around 300–500°C, the long-chain molecules in the waste begin to break down into smaller compounds. These compounds are released as oil gas, which can later be condensed into liquid fuel oil after going through the condensation system.

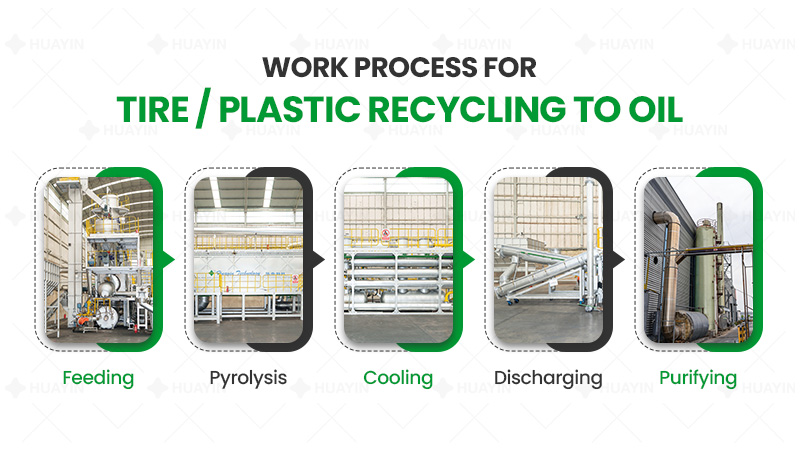

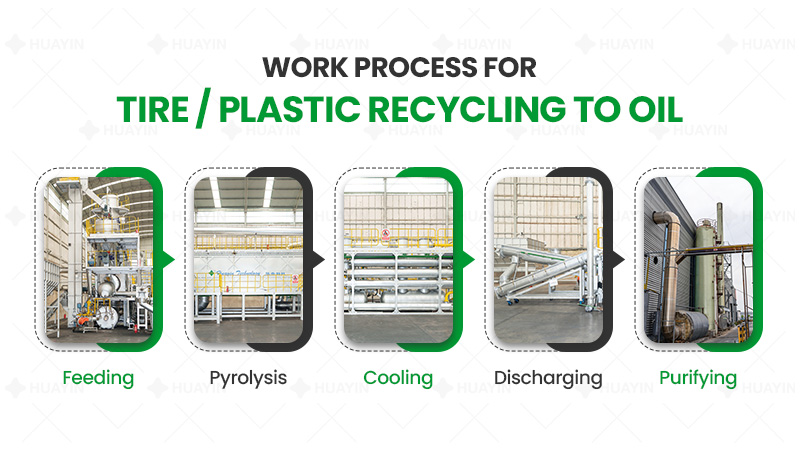

2. Working Process for Pyrolysis Equipment in Fuel Oil production

(1) Feeding and Pyrolysis Reaction

Raw materials are fed into the pyrolysis reactor through the automatic feeding system or manually. The reactor is gradually heated to ensure stable temperature control and smooth operation. Under high temperature, the waste decomposes and produces oil gas, solid carbon residue, and steel wire (in the case of tire pyrolysis).

(2) Condensation and Gas Purifying

Oil gas goes through the condensation system and will be cooled into liquid fuel oil. Non-condensable gas can be recycled as a heat source for the system, helping reduce fuel consumption and operating costs.

(3) Final Products Discharging

After pyrolysis is completed, solid residues such as carbon black, steel wire or other products are discharged safely and can be further processed or sold.

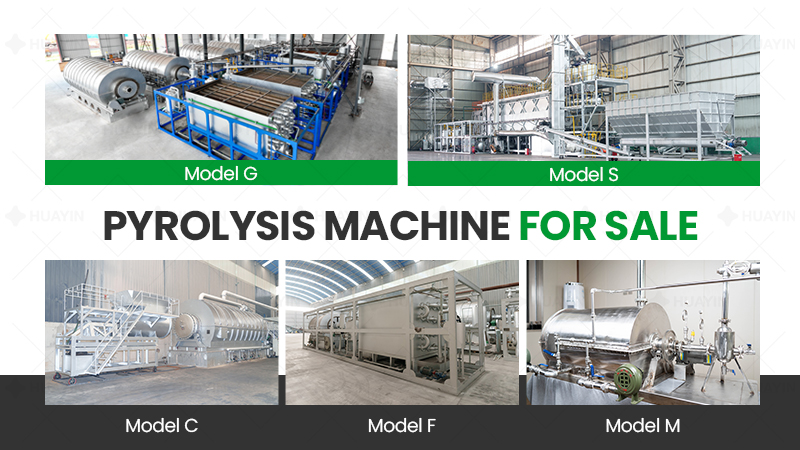

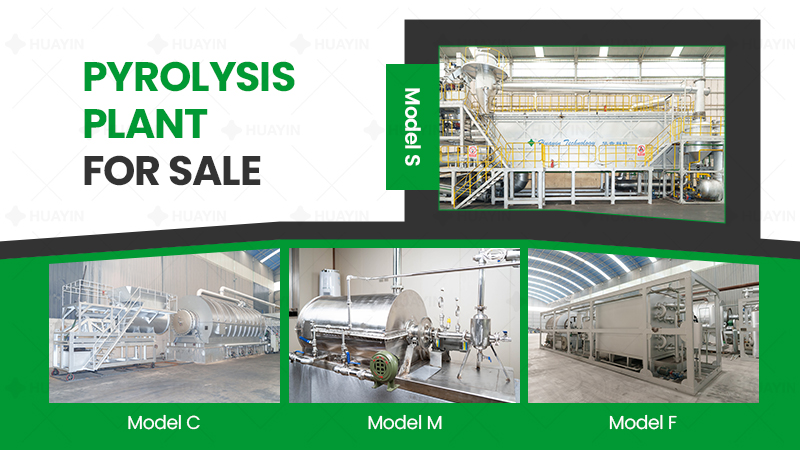

With the whole process, pyrolysis equipment can convert waste into valuable products. Now there are various types of pyrolysis equipment for sale in the market with different capacities and designs. If you are interested in the pyrolysis recycling project, just choose a suitable machine based on your situation. (Recommend reading: Small vs Large Pyrolysis Machine: Which One Is Right for You?)

For more detailed information, welcome to contact Huayin directly!