While farmlands bring us bountiful harvests, they also leave behind an environmental problem – discarded agricultural plastic films (PE). These plastic films are extremely difficult to degrade and can seriously damage soil structure and hinder crop growth, thus being known as the stubborn disease of “white pollution”. So, how should we deal with these agricultural films scientifically and efficiently?

Dilemmas and Challenges of Traditional Disposal Methods

For a long time, the traditional methods for dealing with discarded agricultural films have mainly included the following types, but all of them have obvious limitations:

- Random disposal or landfill: This is the least desirable approach. It takes hundreds of years for plastic film to degrade in nature, which will occupy land resources for a long time and pollute soil and groundwater.

- Direct incineration: Open-air burning by farmers in fields produces large amounts of toxic and harmful gases, including dioxins, which seriously pollute the atmosphere and harm human health. It has been explicitly prohibited.

- Physical recycling: Physical cleaning and granulation are relatively common recycling methods. However, agricultural film often contains large amounts of sediment, water, and impurities, making the cleaning process extremely difficult, requiring significant water consumption and generating secondary pollution (wastewater). Furthermore, due to the high levels of impurities, the quality of the recycled granules is low, their market value is limited, and this severely squeezes the profit margins of recycling companies.

Faced with these challenges, a more comprehensive and cost-effective solution for agricultural plastic film is urgently needed.

Technological Revolution: Pyrolysis – A Path to Plastic Film Disposal

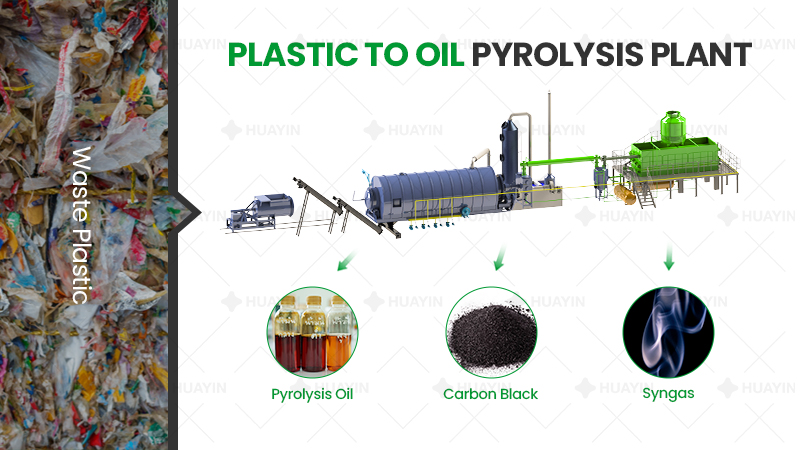

When traditional methods reached a dead end, a new chemical recycling technology opened up a new frontier: pyrolysis. The core of pyrolysis technology is to heat waste agricultural film in an oxygen-free or oxygen-deficient environment, breaking down its polymer chains and returning it to its original oil and gas state, ultimately converting it into valuable fuel oil.

Why is pyrolysis an ideal solution for disposing of agricultural plastic film?

- High Tolerance for Impurities: Unlike the demanding physical cleaning and granulation processes, the pyrolysis method is more tolerant of small amounts of sediment and moisture in the plastic Our pyrolysis machine can even process raw materials that have not undergone extensive cleaning, greatly simplifying the pretreatment process and reducing initial investment and operating costs.

- Complete Resource Conversion: Pyrolysis is not a simple physical transformation, but a thorough chemical reconstruction. It can convert nearly 100% of the plastic components into valuable products:

- Fuel Oil (approximately 40%-50%): It can be used as a fuel for industrial boilers, cement plants, and power plants, and has a stable market demand.

- Carbon black (approximately 30%-35%): Can be used as an industrial dye or additive, or pressed and molded for use as fuel.

- Syngas (approximately 10%-15%): After purification, it is recycled back into the combustion chamber to power the pyrolysis reactor, achieving energy self-sufficiency.

HUAYIN Solution: Pyrolysis System Designed for Agricultural Plastic Film

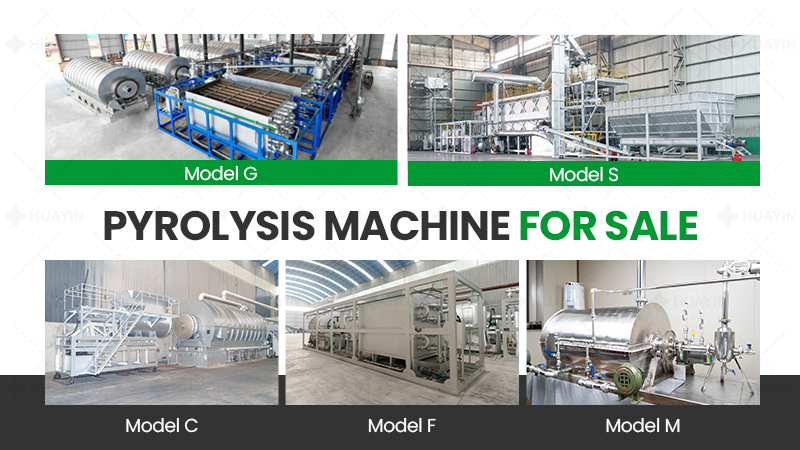

We are well aware of the characteristics of agricultural plastic film—lightweight, thin, and complex. Therefore, Huayin engineers have optimized our pyrolysis equipment specifically for this purpose:

- Hydraulic feed system: This effectively prevents clogging of the plastic film, ensuring stable feeding.

- Rotary pyrolysis reactor: This ensures constant material flow and uniform heating during the reaction.

- Environmental performance: Our multi-stage flue gas purification system ensures a clean, secondary-pollution-free production process, helping your project easily pass environmental impact assessments.

Imagine that discarded agricultural plastic film, once scattered across the fields, is now collected and fed into a modern plastic film pyrolysis plant. In our automated pyrolysis machine, it’s efficiently converted into fuel oil and industrial carbon black, not only addressing environmental pollution but also generating substantial financial returns for you.

Huayin Company sincerely invites all investors and entrepreneurs interested in sustainable agricultural development and seeking waste resource solutions to contact us. We’ll provide you with a detailed project return on investment analysis and invite you to visit our plastic film pyrolysis plant.