Pyrolysis machine can recycle various waste rubber tires, including small car/truck tires, small car/bicycle tires, rubber cables, rubber sheerts, etc., whose tire pyrolysis oil extraction rate typically ranges from 30% to 52% by weight of the input rubber tires.

waste tire pyrolysis oil yield

If you want to improve the rubber tire pyrolysis oil extraction rate, we can optimize the performance of recycled rubber tires and pyrolysis machine designs:

1. Recycled rubber tires

The pyrolysis oil extraction rate is mainly determined by the recycled rubber tires, such as its type, water content, quality. If you want to obtain more rubber tire pyrolysis oil, you can make some pre-treatment for the rubber tires, such as:

(1) Cut rubber tires into small pieces, which can increases the surface area exposed to heat, enabling more uniform and efficient decomposition, thus potentially boosting the oil yield;

(2) Select rubber tires with high oil content;

(3) Select suitable space for rubber tires storage: storing rubber tires in a dry, well – ventilated space prevents moisture absorption and degradation, which could otherwise reduce the quality and quantity of the resulting pyrolysis oil.

2. Pyrolysis machine designs

We can recycle rubber tire to pyrolysis oil with the whole process of feeding, heating and pyrolysis, oil gas cooling and final products collecting. As the main equipment for the recycling process, pyrolysis machine design also influence the pyrolysis oil extraction rate, such as its pyrolysis temperature, heating time, oil gas cooling efficiency, equipment control automation, etc. So select a suitable pyrolysis machine, we can improve the pyrolysis oil extraction rate to a certain extent.

(Recommend reading: What factors will influence the oil output of pyrolysis machine)

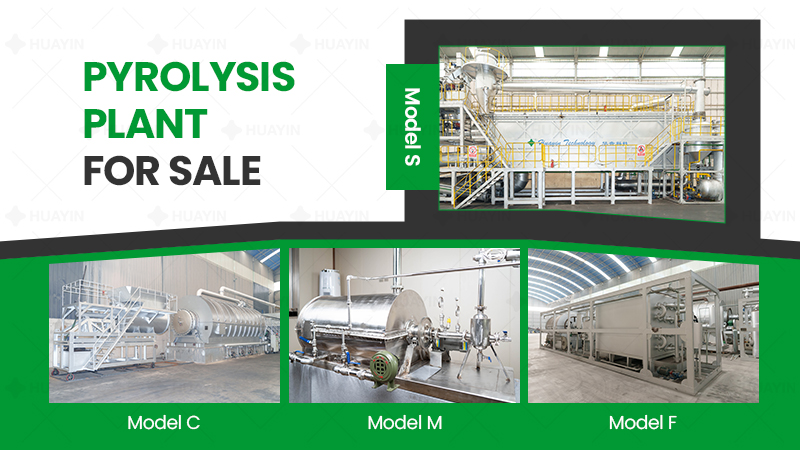

As a popular product in the pyrolysis market, Huayin pyrolysis machine has received lots of good feedback to help customers recycle rubber tires to pyrolysis oil with a higher extraction rate. Take our continuous pyrolysis machine as an example, adopts the fully automatic PLC control system, which can make precise control on the pyrolysis process, such as its pyrolysis temperature, rubber tire residence time, oil gas flow rate, etc., realizing full pyrolysis of rubber tires to get he higher extraction rate while save much labor cost and ensure high work safety. Moreover, we understand that each customer have their own project scheme. That’s why we offer customized solutions tailored to specific requirements, ensuring that our pyrolysis machines deliver the best possible performance in every project.

If you also have waste rubber tires to process, just feel free to contact Huayin directly, we can provide overall services for you to help you successfully set up the pyrolysis machine projects!