When deciding to invest in a waste tire pyrolysis project and purchase the waste tire pyrolysis equipment, customers are always concerned about some information. Today, let Huayin have an introduction about 3 FAQs about waste tire pyrolysis equipment in detail.

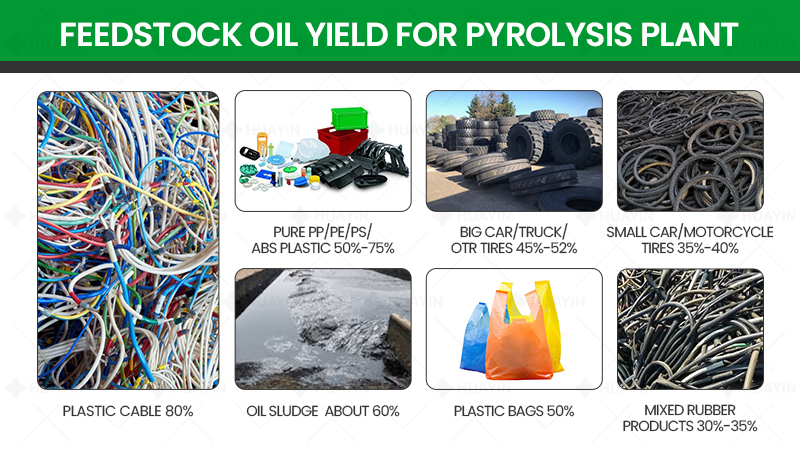

FAQ 1: What types of waste tires can pyrolysis equipment recycle and how about their oil output?

Generally, waste tire pyrolysis equipment can process various waste tires and other rubber products, such as car tires, truck tires, motorcycle tires, bicycle tires, rubber cables, rubber soles, etc. In terms of oil yield, the average oil output is around 40%–45%, and the remaining by-products include carbon black (30%–35%), steel wire (10%–15%), and syn-gas (5%–10%), which can be reused as a heat source for the reactor, making the operation more energy-efficient.

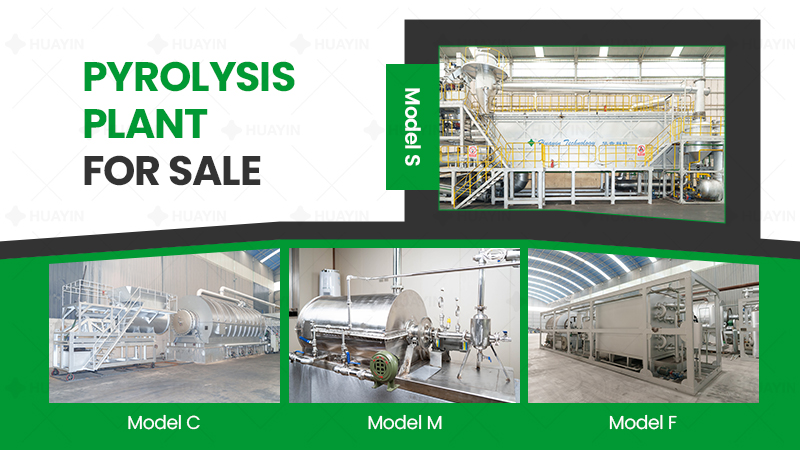

FAQ 2: What types of waste tire pyrolysis equipment can we select in the market?

Now there are two popular choices in the market for the waste tire pyrolysis equipment: batch type design and continuous type design. These two designs have their own advantages and capacities.

For batch type waste tire pyrolysis equipment, it has the processing capacity from 10kg to 20 tons per set, which adopts the container design for easy transportation, installation and operation. And for novice investors, this is a good choice;

For continuous type waste tire pyrolysis equipment, it has the processing capacity from 30 to 50 tons per set, which adopts latest pyrolysis technology and fully automation PLC control system for greater operation performance and higher work efficiency and safety. If customers have rather abundant budget, this type machine is better.

Of course, for these two types of waste tire pyrolysis equipment, they both are equipped with environmental protection system and safety configurations to ensure the whole performance of the machine.

FAQ 3: What profits can we get from waste tire pyrolysis equipment?

For investing waste tire pyrolysis equipment project, the main two profits can customers obtain are economic and environmental benefits:

Economic benefits: waste tire pyrolysis equipment can recycle waste tires into valuable products, such as fuel oil, carbon black, steel wire and syn-gas, which all have wide applications and large market to generate huge profits for customers.

Environmental benefits: on the one hand, waste tire pyrolysis equipment adopts pyrolysis technology to recycle waste tires instead of landfilling or incineration, which can reduce the pollution of soil, air, etc.; on the other hand, high standard environmental protection system can effectively purify the waste gas generated during the operation of the equipment and avoid secondary pollution, truly realizing 100% environmentally recycling.

All in all, waste tire pyrolysis equipment is worth investing. For more FAQs about waste tire pyrolysis equipment, please follow the subsequent update of Huayin company, also you can contact us directly!